WHAT IS THE INTERZINC DESIGN CHALLENGE?

The Zinc Challenge is a competition created for engineering and design students who are currently enrolled at a college or university. Students are encouraged to use their imagination to create, design, and develop a ‘Wearable Electronic Device’ made by zinc die casting (more details below).

Three winners will be selected, and each participant or group will receive an award for use at the college or university at which they are currently enrolled. A $2,000 award will go to each of the top three winners and $1,000 will be donated to their faculty advisor for use at his or her discretion within the department.

WHAT’S INVOLVED?

2. COMPLETE THE QUESTIONNAIRE

Once you complete the registration form, you will automatically be redirected to a downloadable PDF of the questionnaire. You can also access the questionnaire by clicking the icon above.

3. SUBMIT YOUR DESIGN BY THE DEADLINE

Submit your unique design and wait for the results!

CONTEST RULES AND FAQ’S

COMPETITION OVERVIEW

The theme of the 2019-2020 Zinc Challenge is to design and develop a Wearable Electronic device. Portable electronics have long been used for entertainment, such as for listening to music on the go, but have more important uses as mobility aids, heath sensors, activity monitors, and security alerts. Electronics can be passive sensors to active computers that receive information and provide guidance to the wearer. Wearable electronics can be worn directly on the body, or incorporated into clothing, hats, eyewear, jewelry, or other accessory. Ultra thin wall zinc die castings are ideal for portable product applications.

The challenge is to design a stylish yet functional wearable electronic device that enhances or extends a person’s functional ability. The main component of the product design should demonstrate the advantages of zinc alloys and the zinc die casting process. Furthermore, both the material and method of manufacture for your unique design need to be justified. Your presentation should convey an understanding of:

- Appropriate selection of a zinc die casting alloy

- Design suitable for high pressure die casting

- Selection of suitable surface finish

- Compatibility with other materials

ELIGIBILITY

This competition is open to all undergraduate students enrolled at an engineering or design college or university in North America in the current academic year.

NUMBER OF ENTRIES

Any individual or group involved in producing an entry may submit any number of designs and must fill out an entry form for each design. The design must be endorsed by a faculty member at the design college or university.

Single applicants: fill in the information requested.

Group applicants: designate one representative as the applicant, and place this person’s name and contact information in the appropriate sections. The remaining group members must have been listed on the zinc questionnaire and the on the back of the entry form.

Limit one entry per entry form.

SUBMITTING YOUR DESIGN

- Complete the electronic entry form.

- Submit both the design and questionnaire by April 15, 2020 to: Zincchallenge@zinc.org.

DESIGN RULES

Submit PDF only files that clearly represent the design idea, concept description and relevant text.

The information must be organized on three (3) pages so that a complete concept with development can be understood. The viewer is not to be required to make any assumptions or intentions not clearly shown in the file. The first page should show the design development for the idea, the second page should detail the reasons why zinc combined with high pressure die casting is appropriate for the manufacture and use of the part, and the final page should show the part isolated and in use for the intended application.

Written text should be minimal, but is essential. The entry should contain description and documentation, and a statement of the problem solved and reasons why the entrant feels the solution is effective. The text should also highlight unique features that may be unclear unless identified.

AWARDS

There will be three awards of $3000.00 each with the money split between the student or team ($2000.00) and the faculty advisor ($1000.00).

The awards will acknowledge each designer’s name in all publicity.

JUDGING CRITERIA

The criteria for judging the competition will be based on the score and completeness of the quiz portion and the appropriateness of the solution to the design problem; including but not limited to: quality, originality, thoroughness and the development potential.

It is imperative that the information on the boards must convey the complete concept and not require the viewer to make any assumptions or intentions of the design not clearly shown on the boards.

ANNOUNCEMENT OF RESULTS

The final 3 winning entries will be announced at the annual IZA zinc die casting conference, and posted on the Interzinc website.

Entrance into this competition constitutes permission to post names and submitted designs by Interzinc for promotional purposes without further consent of the individuals involved.

JURORS

Final selections for awards will be chosen by Interzinc members and outside experts.

TERMS & CONDITIONS

Any applicant or group who wishes to protect his/her work by obtaining copyrights, design rights, patents and/or any other intellectual property right must do so at his/her own expense. By entering the competition, the applicant agrees that Interzinc may use the submitted design for promotional purposes without restrictions or further compensation.

THIS YEAR’S WINNER

ZINC CHALLENGE: 2019-2020 – Wearable Electronic Device

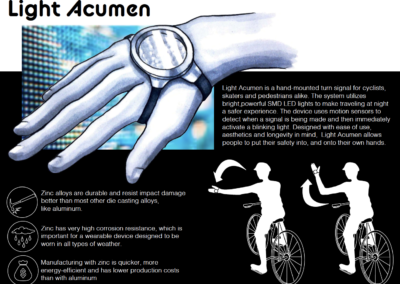

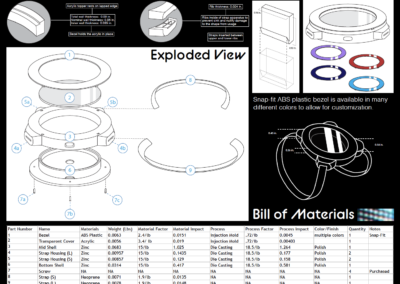

Title: Light Acumen

Designer: Sidona Bradley

School: University of Oregon

Instructor: Kiersten Muenchinger

Judges’ Comments:

- “I really like this design. It is unique and original, and it’s clear the designer has thought through many of the challenges of wearing and using such an inventive product.”

- “The use of zinc (rigid material) makes sense in this wearable.”

PREVIOUS WINNERS

Please note that winners are not listed in any specific order.

ZINC CHALLENGE: 2017-2018 – GLASS SUPPORT BRACKETS

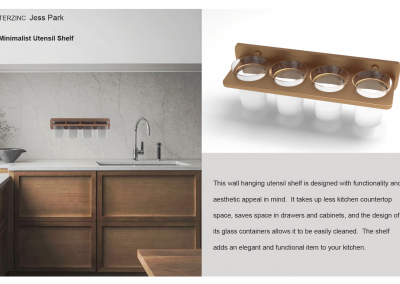

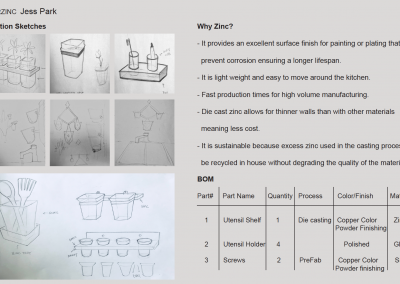

Title: Minimalist Utensil Shelf

Designer: Jess Park

School: University of Oregon

Instructor: Jim Arnold

Judges’ Comments:

- “I like the concept of this design. A very minimal design for utensils only, allowing for more drawer space for other kitchen products. The glass container can also be washed.”

- “The student makes use of zinc die casting’s high fluidity to make thinner walls as well as the use of ribs to help strengthen the part.”

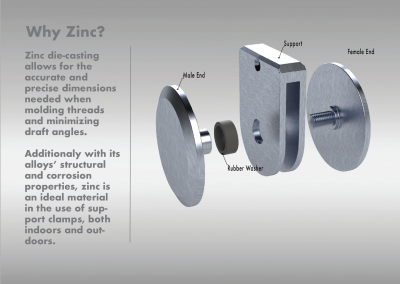

Title: Glass Support Brackets

Designer: Justin Schwarting

School: University of Wisconsin – Stout

Instructor: Benjamin Pratt

Judges’ Comments:

-

“I like the interesting design for hanging glass giving increased flexibility with unlimited wire angles.”

-

“The student takes advantage of the ability to cast accurate dimensions and zinc’s corrosion resistance, which are both important for this application.”

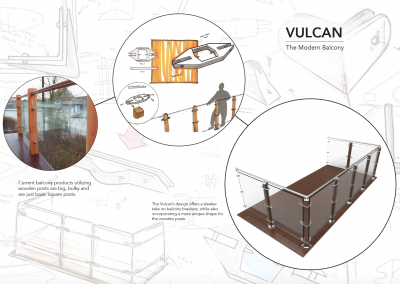

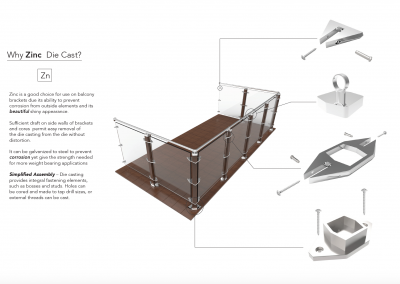

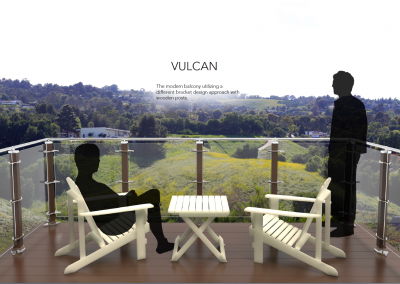

Title: Vulcan: The Modern Balcony

Designer: Simon Elser

School: Purdue University

Instructor: Ted Lu

Judges’ Comments:

-

“I like the use of various bracket designs for the different locations and functions on the balcony rail.”

-

“The student recognizes the ability of die cast zinc alloys to resist corrosion and still look shiny and beautiful.”

ZINC CHALLENGE: 2016-2017 – COMMERCIAL KITCHEN PRODUCTS

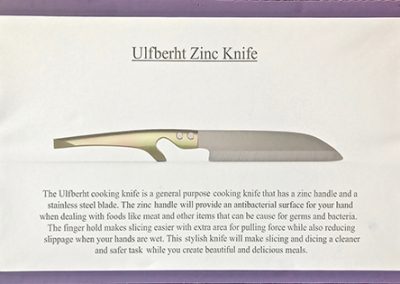

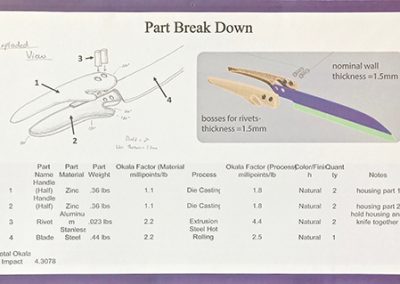

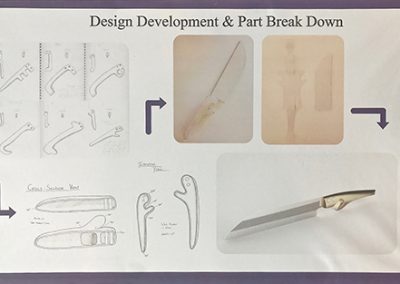

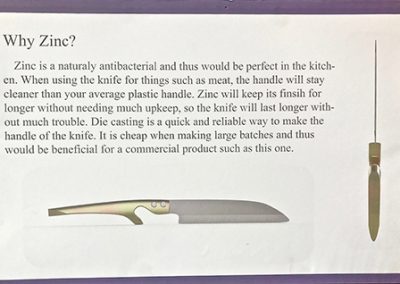

Title: Ulfberht Knife

Designer: Bryan Varga

School: University of Oregon

Instructor: Beth Esponette

Judges Comments:

- ‘I liked the ergonomic look of this knife, and there may be an application for zinc in knife handles in general.’

- ‘Very well executed design process. Benefits of using zinc shown in good detail.’

- ‘Well executed design development with interesting historical reference.’

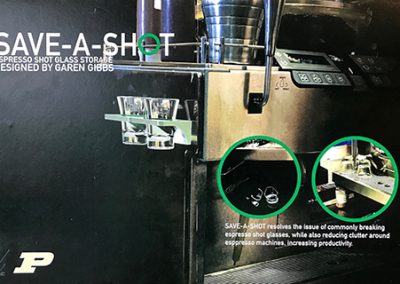

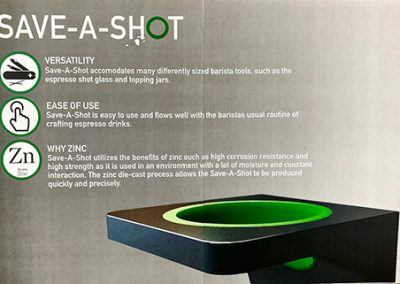

Title: Save-A-Shot

Designer: Garen Gibbs

School: Purdue

Instructor: Ted Lu

Judges Comments:

- ‘This is a good add-on product and clearly a good choice in zinc.’

- ‘Excellent concept presentation. Imaginative solution to a barista’s problems.’

- ‘Simple aftermarket add-on product with wide market potential and easy integration.’

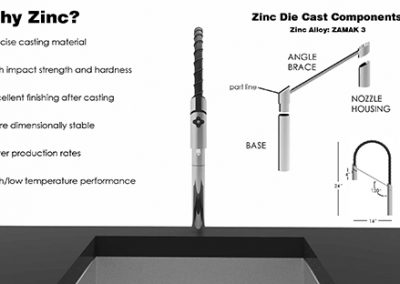

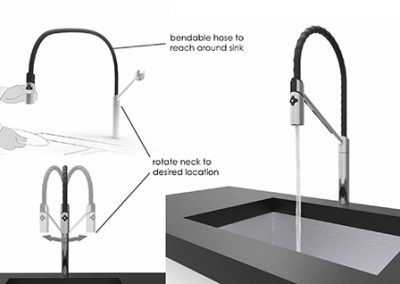

Title: Zinc Faucet

Designer: Cole Sippel

School: University of Wisconsin – Stout

Instructor: Benjamin Pratt

Judges Comments:

- ‘Although zinc is already used in faucets, I liked the novel idea of using electronic controls on the nozzle. The reason for using zinc was clearly presented.’

- ‘New imaginative approach to a one control faucet. Excellent execution of the design process.’

- ‘One hand control of all functionality of the faucet improves on existing designs.’

ZINC CHALLENGE: 2015-2016 – OUTDOOR CAMPING PRODUCTS

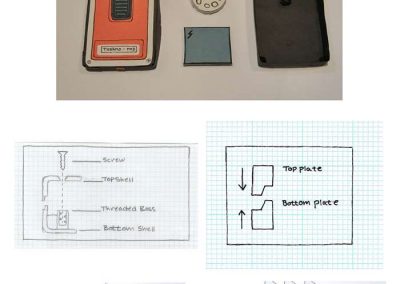

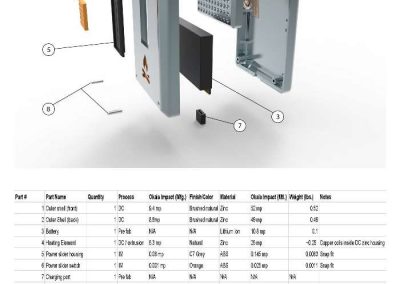

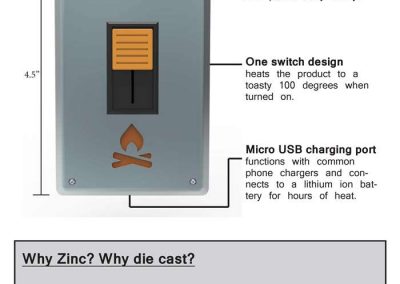

Title: Tinderbox

Designer: Garrett Warnick

School: University of Oregon

Instructor: Elizabeth Esponnette

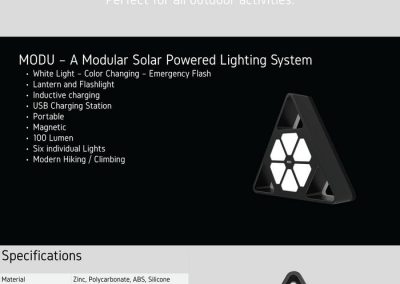

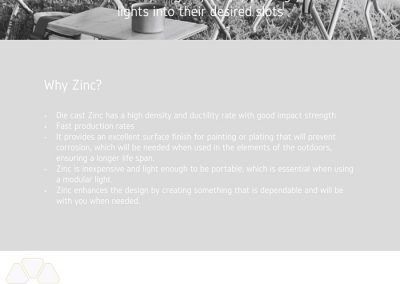

Title: MODU

Designer: Jacob Stranahan

School: University of Oregon

Instructor: Elizabeth Esponnette

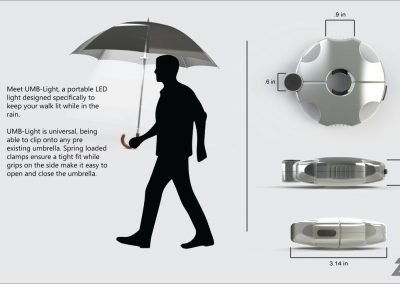

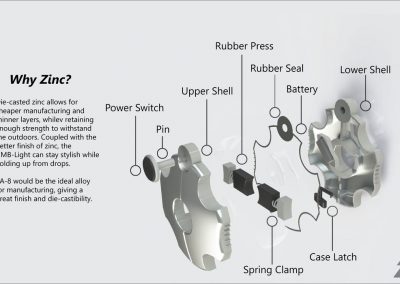

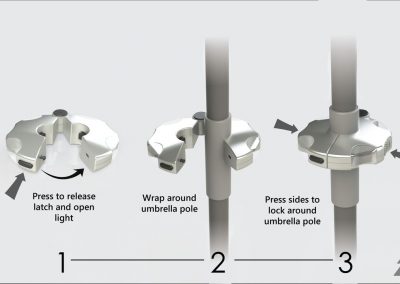

Title: UMB Light

Designer: Robert Caswelch

School: Southern Illinois University-Carbondale

Instructor: Tao Huang

THIS YEAR’S WINNERS

Please note that winners are not listed in any specific order.

ZINC CHALLENGE: 2017-2018 – GLASS SUPPORT BRACKETS

Title: Minimalist Utensil Shelf

Designer: Jess Park

School: University of Oregon

Instructor: Jim Arnold

Judges’ Comments:

- “I like the concept of this design. A very minimal design for utensils only, allowing for more drawer space for other kitchen products. The glass container can also be washed.”

- “The student makes use of zinc die casting’s high fluidity to make thinner walls as well as the use of ribs to help strengthen the part.”

Title: Glass Support Brackets

Designer: Justin Schwarting

School: University of Wisconsin – Stout

Instructor: Benjamin Pratt

Judges’ Comments:

-

“I like the interesting design for hanging glass giving increased flexibility with unlimited wire angles.”

-

“The student takes advantage of the ability to cast accurate dimensions and zinc’s corrosion resistance, which are both important for this application.”

Title: Vulcan: The Modern Balcony

Designer: Simon Elser

School: Purdue University

Instructor: Ted Lu

Judges’ Comments:

-

“I like the use of various bracket designs for the different locations and functions on the balcony rail.”

-

“The student recognizes the ability of die cast zinc alloys to resist corrosion and still look shiny and beautiful.”